LIGHTNING PROTECTION FOR EXTERNAL FLOATING ROOF TANKS

BACKGROUND

A lightning strike consists of two components: a short duration, high-energy spike, followed by a longer duration, lower energy tail (see graph). While the high-energy spike is truly impressive, it is the lower energy, long duration component that is actually responsible for ignitions in these tanks.

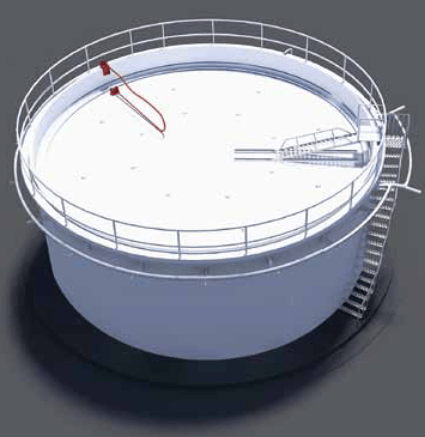

The roof of the tank floats on pontoons on the stored product. It is centered in the tank shell by centering shoes. Vapor is contained by a primary and a secondary seal. These tanks have traditionally been equipped with flexible, stainless steel grounding shunts extending over the secondary seal and spaced at frequent intervals (10’ maximum) around the perimeter of the floating roof. Additionally, the floating roof is usually bonded to the tank shell with one grounding conductor run along the stairway from the top of the tank shell to the floating roof.

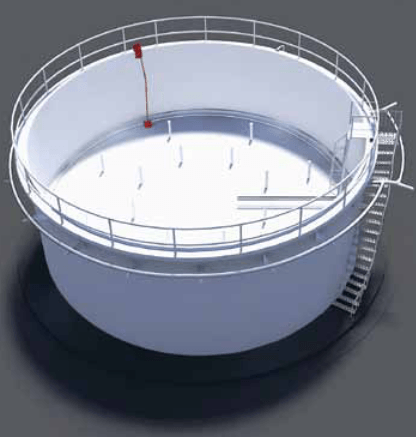

<src=”https://lightningmaster.com/wp-content/uploads/2015/11/Graph_MAGS.png” alt=”” />Lightning becomes an issue when it strikes either the floating roof, the tank shell, or nearby. Ignition is not normally caused by the heat of the lightning channel igniting venting vapors. It is caused by arcing from the secondary effect of lightning. A thunderstorm is an electrically charged cloud mass, with a charge, usually negative, at its base. That charge induces an opposite charge, usually positive, on the surface of the earth beneath it. When lightning attaches to atank or other object on the surface of the earth, the charge at the point of attachment changes dramatically and almost instantly. The surrounding ground charge rushes toward the point of the strike. If that in-rush of charge crosses a gap, it may arc. If that gap is between the floating roof and the side of the tank shell, and there are flammable vapors present, those vapors may ignite.

Another way of looking at this phenomena is to consider a lightning attachment to the shell of the tank. The tank shell changes potential almost instantly. The floating roof, being somewhat electrically isolated from the shell, does not. That difference in potential between the floating roof and the tank shell must equalize. Unless a preferred path is provided, a potential equalizing arc may occur, once again igniting any flammable vapors present.

SOLUTIONS

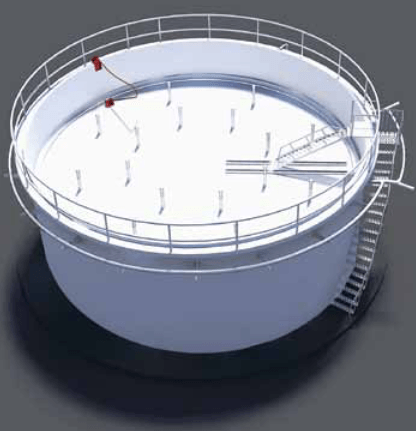

To address the lower energy, long duration component of the lightning strike, API 545 recommends the installation of by-pass conductors between the floating roof and tank shell at intervals not to exceed 100’ around the roof perimeter. These conductors provide a low-resistance bonding path between the roof and tank shell, and are intended to prevent ignition-causing arcs generated by this current flow.

Is there a difference in performance between a retractable reel system and a simple conductor? Theoretically, yes, practically, no. The electrical performance of a simple conductor is adequate to the required task. Additionally, the simplicity of the simple conductor system, enhanced by a mechanism to reduce stresses and keep it out of trouble, indicates a system that will provide years of reliable and trouble-free service, at a greatly reduced cost.

The lightning protection bonding on a tank is a cost item. It does not make the tank better, last longer, or store more product. It simply provides lightning bonding. Therefore, employ the least complex, lowest cost system that performs as required.